Our services

Our team of experienced engineers take pride in developing solutions to meet our clients most challenging needs.

Indicative services

-

Our engineers successfully carry out the following Engineering tasks on a day to day basis:

Initial Survey & Report

Advice & Assistance

Cable Sizing Calculations

Protective Device Selection & Settings

Schedules

Material Take Off

Layout Drawings

Routing Drawings

I.S. Loop Calculations

Loop Diagrams

ATEX Inspection Reports

Data sheets

RFQ (Request for Quotation)

The above list is not exhaustive and our team may be able to assist with other deliverables to meet our clients needs, please use our online contact form if the deliverable you require is not listed above and we will do our best to assist.

-

Electrical Control & Instrumentation installation activities within Hazardous & Non-Hazardous environments across a range of sectors

Process control installations

Building Services (Including Cleanroom/Laboratory) in line with BS 7671

ATEX Inspections at all inspection grades (Detailed, Close & Visual) in line with BS EN 60079.

-

DSEAR Risk Assessments

Materials review for identification of substances that should be considered under DSEAR

Risk Assessments associated with storage and handling of dangerous substances

Determination of size and specific zone type based on the operating conditions, substance used and review of ventilation within the process areas

Preparation of LEAC (List of Equipment associated with classification) and drawing mark-ups to show hazardous zone type/extents

Dust Hazard Analysis

Advice on equipment selection for zoned areas

Comprehensive reports to demonstrate compliance with DSEAR

Process Safety Risk Assessments

Preparation of Basis of Safety documents.

-

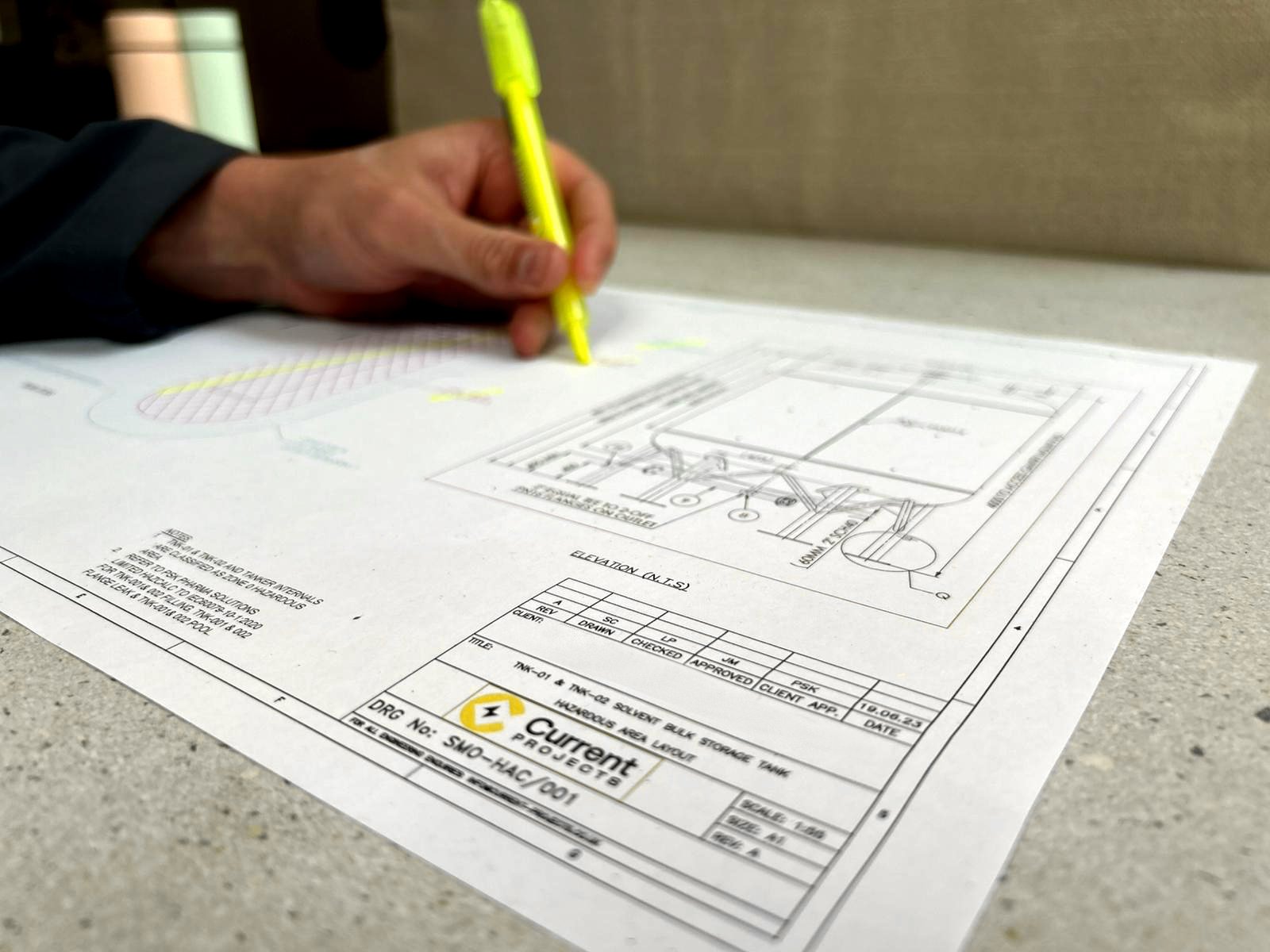

Our fully trained CAD Technicians can assist with all computer aided design activities. Current Projects use AutoDesk products for all computer aided design.

-

Our engineers and technicians have years of experience in commissioning EC&I systems across various sectors including COMAH sites and Zoned Hazardous Areas. Typical duties include:

Functional testing of pre commissioned systems

Point to point testing of MCC Starters

Barrier/trip amplifier setup

Instrumentation setup/ranging

Testing and setup of hardwired trip logic and relays

Actuated valve setup (including feedback)

Control valve setup

Pneumatic interfaces

The above list is not exhaustive and our team may be able to assist with other commissioning activities to meet our clients needs. Please use our contact form if the activity you require is not listed above and we will do our best to assist.

Project Enquiries

If you are interested in working with Current Projects we would love to hear from you. Please complete the form below with details of your requirements and a member of our team will be in touch at the earliest opportunity to discuss your enquiry in more detail.